|

Abstract 摘要

引进生物能源驱动的产品,如生物乙醇,生物柴油,热电联产的生产或固体生物燃料是实现欧盟设定的2010年(从RES20%的电力生产)目标至关重要。然而,为了达到这些目标,策略计划有关于生物质转化形成。本文的目的是检查参与已有的或新的生物质资源开发物流,分析各种方案在希腊利用生物质能和生物燃料的经济可行性。保留#2008爱思唯尔有限公司保留所有权利。The introduction of biomass driven energy products like bioethanol, biodiesel, Combined Heat and Power production or solid biofuels is vital for achieving the targets set from the EU for the year 2010 (20% electricity production from RES). However, in order to reach these targets, a policy plan has to be formed concerning the conversion of biomass. The aim of this paper is to examine the logistics involved in the exploitation of already available or new biomass resources and to analyse various scenarios for the economic feasibility of the use of biomass and biofuels in Greece. # 2008 Elsevier Ltd. All rights reserved.

1. Introduction 介绍

为了引进像希腊一个国家的政策计划,其中生物质可以由欧盟指令规定的2010年目标的实现发挥显著作用,经济分析是至关重要的。更精确地说,的主要来源,以及相关的功能和主要来源(物流)在供应链的成本受试者生产成本将要加以考虑。关于液体和固体生物燃料的最终处置问题也被认为是旁边的单位的经济可行性。In order to introduce a policy plan in a country like Greece, in which biomass can play a significant role for the achievement of the 2010 aims set by the EU directives, an economic analysis is vital. The aim of this paper is to examine the investment and operating costs of various technologies employed in the units of energy conversion of biomass into final products. More precisely, the production cost of primary sources as well as subjects related to the functionality and the cost of the supply chain of primary sources (logistics) are going to be considered. Issues concerning the final disposition of the liquid and solid biofuels are also considered alongside the economic viability of the units.

2. The production cost of primary sources 主要来源的生产成本

2.1. Data for the production cost of primary sources One of the most important parameters that indicate the viability of the units that convert primary biomass into final energy products is the procurement cost of primary sources at the gate of these units. This cost consists of the following parts: the production cost of primary sources; the pre-treatment cost, either in their production area (e.g. chipping) in which case the cost is added to the procurement cost, or in the conversion unit (e.g. drying), in which case it is part of the general operating cost of the plant; the transportation cost of primary sources to the conversion unit; the profit of the primary source producer and the transporter. The production cost of primary sources has to be separated taking into account the fact that biomass may be already available (like for example the agricultural residues of the olive oil cultivation sector, or the sub-products of a specific production process, e.g. wood industry residues, or second generation fuels and organic waste), or new (energy crops). In this study, only the procurement cost of primary sources for energy corps will be examined, since the cost of already available biomass is linked with fuel availability studies. Finally it is assumed, that farmers are responsible for both production and transportation of primary sources to the conversion plants. This way the producer is the transporter and the profit of the producer is calculated for both the production and the transportation to the plants.

2.2. Production cost of energy crops

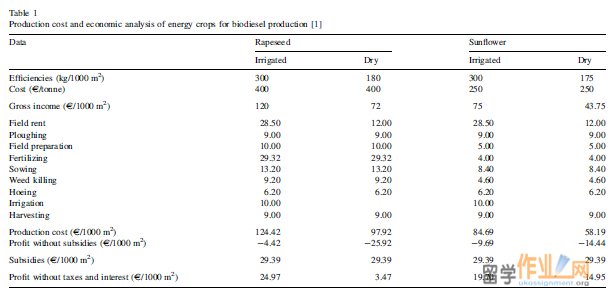

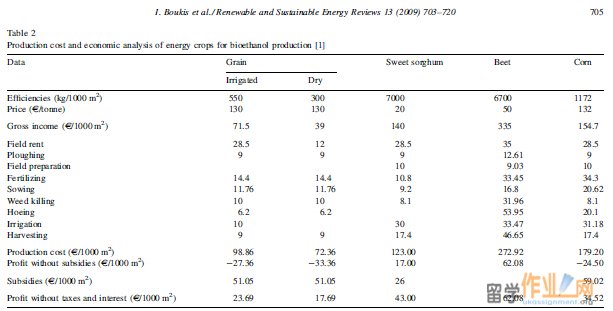

The main energy crops that will be discussed in this study are the following: rapeseed (Brassica napus) and sunflower for biodiesel production (in this study, sunflower will be exclusively researched, since it is an already known cultivation to Greek farmers); sweet sorghum for bioethanol production (comparison with the already available relative cultivations); fiber sorghum for electricity production or for the production of modified fuels (pellets and brickets). According to data provided by the Center for Renewable Energy Sources (CRES) [1], the production cost and the economic analysis of energy crops for biodiesel and bioethanol production in Greece are presented in Tables 1 and 2. This data is also based on the 1st annual Report of the Greek Ministry of Development [2]. More recent references [3] raise the total production cost of sweet sorghum up to s 17 tonne 1 or, with an efficiency of Table 1

Production cost and economic analysis of energy crops for biodiesel production [1] Data Rapeseed Sunflower Irrigated Dry Irrigated Dry Efficiencies (kg/1000 m2) 300 180 300 175 Cost (s/tonne) 400 400 250 250 Gross income (s/1000 m2) 120 72 75 43.75 Field rent 28.50 12.00 28.50 12.00 Ploughing 9.00 9.00 9.00 9.00 Field preparation 10.00 10.00 5.00 5.00 Fertilizing 29.32 29.32 4.00 4.00 Sowing 13.20 13.20 8.40 8.40 Weed killing 9.20 9.20 4.60 4.60 Hoeing 6.20 6.20 6.20 6.20 Irrigation 10.00 10.00 Harvesting 9.00 9.00 9.00 9.00 Production cost (s/1000 m2) 124.42 97.92 84.69 58.19 Profit without subsidies (s/1000 m2) 4.42 25.92 9.69 14.44 Subsidies (s/1000 m2) 29.39 29.39 29.39 29.39 Profit without taxes and interest (s/1000 m2) 24.97 3.47 19.70 14.95

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

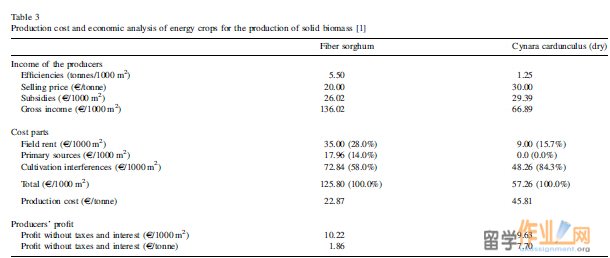

Table 2 Production cost and economic analysis of energy crops for bioethanol production [1] Data Grain Sweet sorghum Beet Corn Irrigated Dry Efficiencies (kg/1000 m2) 550 300 7000 6700 1172 Price (s/tonne) 130 130 20 50 132 Gross income (s/1000 m2) 71.5 39 140 335 154.7 Field rent 28.5 12 28.5 35 28.5 Ploughing 9 9 9 12.61 9 Field preparation 10 9.03 10 Fertilizing 14.4 14.4 10.8 33.45 34.3 Sowing 11.76 11.76 9.2 16.8 20.62 Weed killing 10 10 8.1 31.96 8.1 Hoeing 6.2 6.2 53.95 20.1 Irrigation 10 30 33.47 31.18 Harvesting 9 9 17.4 46.65 17.4 Production cost (s/1000 m2) 98.86 72.36 123.00 272.92 179.20 Profit without subsidies (s/1000 m2) 27.36 33.36 17.00 62.08 24.50 Subsidies (s/1000 m2) 51.05 51.05 26 59.02 Profit without taxes and interest (s/1000 m2) 23.69 17.69 43.00 62.08 34.52 8 tonnes/1000 m2,to s 136/1000 m2. Furthermore, concerning the production cost of sunflower, a slightly higher price of s86.80/1000 m2 is presented in literature [3]. Finally, for the field efficiencies of sunflower seed, an average value of 350 kg/ 1000 m2 may be used. It is also remarked that nowadays, the price of sunflower (more specifically the price of its seeds) is showing a decreasing tendency. In the German market [4] a price range of s160– 185 tonne 1 can be found, when in Greece a range of s180– 200 tonne 1 is referred [3]. The production cost and the economic analysis of energy crops for the production of solid biomass (for electricity production or for the production of second generation biofuels in Greece) is presented in Table 3. It has to be mentioned, that in the case of large scale introduction of biofuels in the energy balance of the European Union and in Greece, the above mentioned production costs (s/ tonne of primary sources) are expected to reduce significantly, since the cultivation efficiencies of energy crops will increase. As a comparison, it can be mentioned that the efficiencies of corn cultivation in USA has increased about 300% in 30 years [5].

2.3. Pre-treatment cost of primary sources (upstream conversion plant)

The chipping of primary sources in the field and the production of chips is a very important and vital method for the

Table 3 Production cost and economic analysis of energy crops for the production of solid biomass [1] Fiber sorghum Cynara cardunculus (dry) Income of the producers Efficiencies (tonnes/1000 m2) 5.50 1.25 Selling price (s/tonne) 20.00 30.00 Subsidies (s/1000 m2) 26.02 29.39 Gross income (s/1000 m2) 136.02 66.89 Cost parts Field rent (s/1000 m2) 35.00 (28.0%) 9.00 (15.7%) Primary sources (s/1000 m2) 17.96 (14.0%) 0.0 (0.0%) Cultivation interferences (s/1000 m2) 72.84 (58.0%) 48.26 (84.3%) Total (s/1000 m2) 125.80 (100.0%) 57.26 (100.0%) Production cost (s/tonne) 22.87 45.81 Producers’ profit Profit without taxes and interest (s/1000 m2) 10.22 9.63 Profit without taxes and interest (s/tonne) 1.86 7.70

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 management and the pre-treatment of most of the primary sources for the following reasons: It increases significantly the Specific Gravity of the transported material, from 75 to 125 kg/m3 for woody biomass (e.g. sweet and fiber Sorghum, corn, etc.), up to 300 to 350 kg/m3 for chips (there is an increase in the energy density of primary sources of 200%) and, consequently, that leads to a more economical and environmentally advantageous transportation of chips into the conversion plants. The treatment of chips at the conversion plants (storage, transportation, feeding into other conversion units in order to improve the physical–chemical properties of biomass, e.g. drying) is much easier than that of the non-pre-treated biomass. The cost of biomass chipping is a function of various parameters, the most important of which is the potential of the needed instrumentation. It is estimated that the cost of chipping for energy crops (all year-round treatment) is about s4– 6 dry tonne 1 [6]. #p#分页标题#e#

2.4. Transportation cost of primary sources

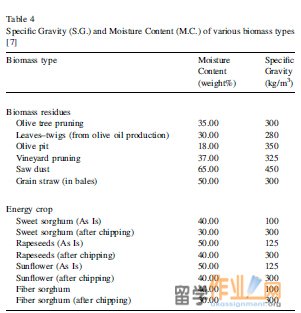

Primary sources (various biomass types), after having been collected in central collection points, they are being transported with trucks to the conversion plants. The transportation cost of primary sources depends on many factors. In the case in which biomass transport is done with trucks which cover short distances to the plant (e.g. from a radius of around 30 km), the cost is estimated according to the following assumptions: average distance of the conversion plant from the biomass production area: 30 km; distance covered by the truck: (2 30) = 60 km; mean velocity of the truck: 40 km/h; duration of the truck service: (60/40) = 1.5 h; loading time of biomass in truck: 0.4 h; unloading time of biomass at the conversion plant: 0.1 h; total duration of a completed service: (1.5 + 0.4 + 0.1) = 2 h; number of services each day (for 8 h a day working time): (8/ 2) 4; mean load capacity of the trucks: 30 m3. Assuming the mean total day expenses (personal costs, consumables, using of the truck, etc.) of a truck at around s220 day 1, the relative cost of transportation for every biomass type is provided from Eq. (1): total day expenses esT eno: of services=dayT eload capacityT ebiomass specific gravity eS:G:TT e100 moisture content% eM:C:TT=100 (1) or 220 4 30 S:G: e100 M:C:%T=100 100 .1; 833 es=dry kgT S:G: e100 M:C:%T The Specific Gravity (S.G.) and the Moisture Content (M.C.) for given biomass types is presented in

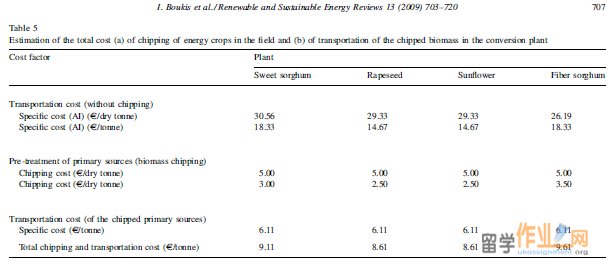

Table 4. In the case of woody energy crops, the assumed S.G., after their chipping, is around 300 kg/m3. According to the above mentioned, the transportation cost of energy crops from their production area to the conversion plant is calculated in non-processed state (As Is = AI), as well as after their chipping, based on the data of Table 4 and Eq. (1) and is presented in Table 5. As it can be seen from this data, the transportation cost of the non-pre-treated (non-chipped) primary sources to the conversion unit is very high, due to the initial low Specific Gravity of energy crops. In the case of the chipping of primary sources in the field, there is a significant rise in energy density. In this case, the total chipping and transportation cost of chipped biomass, from the field into the conversion units is as low as 50% of the initial transportation cost.

3. Functionality of the supply chain 供应链的功能

It is expected that if investment plans for energy exploitation of biomass are being realized (with energy crops or/and biomass residues as primary sources), large amount of biomass will be transported from their production field to the conversion plants where they will be converted into final energy products. Therefore, a systematic organization of the treatment of Table 4 Specific Gravity (S.G.) and Moisture Content (M.C.) of various biomass types [7] Biomass type Moisture Specific Content Gravity (weight%) (kg/m3) Biomass residues Olive tree pruning 35.00 300 Leaves–twigs (from olive oil production) 30.00 280 Olive pit 18.00 350 Vineyard pruning 37.00 325 Saw dust 65.00 450 Grain straw (in bales) 50.00 300 Energy crop Sweet sorghum (As Is) 40.00 100 Sweet sorghum (after chipping) 30.00 300 Rapeseeds (As Is) 50.00 125 Rapeseeds (after chipping) 40.00 300 Sunflower (As Is) 50.00 125 Sunflower (after chipping) 40.00 300 Fiber sorghum 40.00 100 Fiber sorghum (after chipping) 30.00 300

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

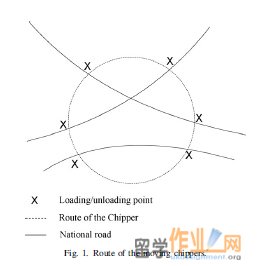

Table 5 Estimation of the total cost (a) of chipping of energy crops in the field and (b) of transportation of the chipped biomass in the conversion plant Cost factor Plant Sweet sorghum Rapeseed Sunflower Fiber sorghum Transportation cost (without chipping) Specific cost (AI) (s/dry tonne) 30.56 29.33 29.33 26.19 Specific cost (AI) (s/tonne) 18.33 14.67 14.67 18.33 Pre-treatment of primary sources (biomass chipping) Chipping cost (s/dry tonne) 5.00 5.00 5.00 5.00 Chipping cost (s/dry tonne) 3.00 2.50 2.50 3.50 Transportation cost (of the chipped primary sources) Specific cost (s/tonne) 6.11 6.11 6.11 6.11 Total chipping and transportation cost (s/tonne) 9.11 8.61 8.61 9.61 primary sources is needed in order to reduce the pre-treatment cost and the transportation cost to these units. Primary sources are possible to be delivered directly to the conversion units, collected from the producers that are in a range of 10 km. However, in the cases in which a large amount of fuel is needed to be treated, the complete organization of primary sources treatment is needed, in order to reduce the total pre-treatment (chipping) and transportation cost. According to the literature, various organization schemes for biomass treatment have been proposed [8,9]. It is supposed that the producers of biomass from energy crops will be organized in a way to be responsible also for the transportation of primary sources into the conversion units, by creating Companies for the Treatment and Supplying of the Fuel (CTSF). According to this data, the treatment equipment of primary biomass belongs to CTSF. So the producers, who constitute the CTSF, will be responsible for the total treatment of the fuel, from the production to the delivery at the gate of the plant. Furthermore, a simple scheme of treatment and operation of the supply chain, as it may be undertaken by CTSF, is considered. This scheme refers to woody plants, like forestry, but also to energy crops like corn, sweet and fiber sorghum, etc. In a same way, it is possible to treat several agricultural residues like for example olive tree pruning [10]. According to the given treating scheme, special mow-thresh machines are used to mow primary sources, in order to collect them in the side of the field and, successively, they are chipped from moving chippers. The chips are loaded to containers, which are driven (in a group of two or three containers) for long distances (20–50 km) by using trucks of the conversion plant. Consequently, the treatment of the produced primary biomass needs the following equipment: (a) mow-thresh machines for the collection of cultivated biomass; (b) moving chippers, or stable chippers (for larger biomass amounts) that will treat biomass in the field; (c) containers, where the chipped biomass will be temporarily stored; (d) trucks which transport the chipped biomass into the conversion plant. The chippers follow a radial route, loading the containers in a way that in the end full loaded containers are provided to the trucks (Fig. 1). Since biomass is chipped, it is transferred by open tipping trucks into the conversion plant. In the plant there are two (or more) unloading systems, so as to prevent delays during the unloading of the fuel, or problems concerning the fuel feeding in the case in which the sole system is damaged. The unloading points will include a ditch for the wheels of the trucks. The truck will be unloaded with hydraulic platforms which will be raised with an angle of 608 from the horizontal position. Fig. 1. Route of the moving chippers.

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

4. Transportation and final supply of liquid and solid biofuels 液体和固体生物燃料的运输和最终供应

Biofuels should take profit of the already available installations and gradually replace conventional fuels (mainly diesel and gasoline), increasing also their percentage in the Greek energy market. Examples of parallel use of biofuels and conventional fuels are known worldwide: In transportation (directly taken from the conversion plants). Use of biodiesel in already available gas stations (in separate tanks) in Austria, Germany and Sweden. In the transportation of solid biofuels (pellets) with suitable ships (dry load), or by means of railway net, from their production (in countries of high biomass potential, e.g. USA, Sweden, Canada, Russia, etc.) to central distribution stations (e.g. the port of Rotterdam) and then, by means of transportation companies, to final consumers. Transportation of the produced bioethanol, either directly to the refineries (where it is directly mixed with gasoline, providing the desired anti-knocking properties, or to gas stations where it is provided to the consumers as E85 (mixture of 85% Ethanol, 10–15% Gasoline and 5–0% additives), or as E95 (mixture of 95% Ethanol and 5% additives). In special studies made in USA [11] the needed installations for the transportation and delivery of bioethanol in various levels is discussed. More specifically it is referred that for a low penetration scenario that corresponds to the total ethanol production in USA of around 19.3 109 l/year, around 500 terminals and 35,000 points of delivery are needed, with a total investment cost of s 240 mil or, in reference to a mixture of 85% Ethanol and 15% Gasoline (E85) to s0.02 l 1. It must be also underlined that bioethanol is transported (in Brazil and South Africa) also by means of pipes. However in USA and in EU this would be only achievable if the transported bioethanol volumes reached the 40% of the totally transported gasoline. Finally it should be pointed out that the delivery and transportation of liquid and solid biofuels has started the last years, so there is a high improving potential and cost efficient planning.

5. Evaluation of investment and operating cost of the conversion units of primary biomass to final energy products #p#分页标题#e#

5.1. Small plants for the production of solid, second generation fuels (pellets/brickets)

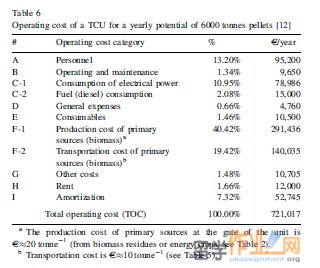

The investment cost of a ‘‘small’’ Treatment and Conversion Unit (TCU) of yearly potential of 6000 tonnes of pellets is estimated at around s625,000. Primary sources for the feeding of the TCU are mainly biomass residues (from agricultural and industrial activities) and also energy crops like for example fiber sorghum. The small TCU, which mainly has a local

Table 6 Operating cost of a TCU for a yearly potential of 6000 tonnes pellets [12] # Operating cost category % s/year A Personnel 13.20% 95,200 B Operating and maintenance 1.34% 9,650 C-1 Consumption of electrical power 10.95% 78,986 C-2 Fuel (diesel) consumption 2.08% 15,000 D General expenses 0.66% 4,760 E Consumables 1.46% 10,500 F-1 Production cost of primary 40.42% 291,436 sources (biomass)a F-2 Transportation cost of primary 19.42% 140,035 sources (biomass)b G Other costs 1.48% 10,705 H Rent 1.66% 12,000 I Amortization 7.32% 52,745 Total operating cost (TOC) 100.00% 721,017 a The production cost of primary sources at the gate of the unit is s 20 tonne 1 (from biomass residues or energy crops, see Table 2). b Transportation cost is s 10 tonne 1 (see Table 5). character, concentrates the biomass residues of a small specific area and has an efficiency of around 41%. This efficiency is defined as the percentage of primary biomass which is converted to final product-pellets. For such efficiency, the yearly biomass feeding should be as high as 14,500 tonnes. The total operating cost (TOC) of the above unit is divided as shown in Table 6. Regarding the data presented in Table 6, the total relative operating cost, minus the fuel cost (TROP FC), for the above small unit (‘‘small’’ TCU) is around: .721; 017 e291; 436 t140; 035T TROP FC . 6000 . s48:25 tonne 1 of pellets This unit can treat biomass residues (e.g. pruning, residues from wood industry, etc.) and can be realized from single farmers, covering the local heat needs (by providing pellets).

5.2. Biodiesel production units

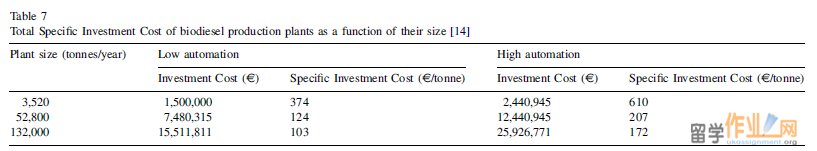

The capital cost of biomass-to-biodiesel plants, is mainly influenced by the plant size, since the technology is considered mature. The Specific Investment Cost (SIC) for a typical biodiesel unit is referred [13] to be around s100 tonne 1 of annual potential. In Table 7, the investment cost for biodiesel production units is presented. With the exception of very small units, the economies-of-scale between ‘‘medium’’ plants ( 52,800 tonnes/year) and ‘‘large’’ plants ( 132,000 tonnes/ year) are very low. According to the operational programme ‘‘competitiveness’’ of the Greek Ministry of Development [15], the selected Investment Cost for a production unit with a capacity of 40,000 tonnes biodiesel/year, is s20,000,000 (it considers as SIC the price of s500 tonne 1).

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 Table 7

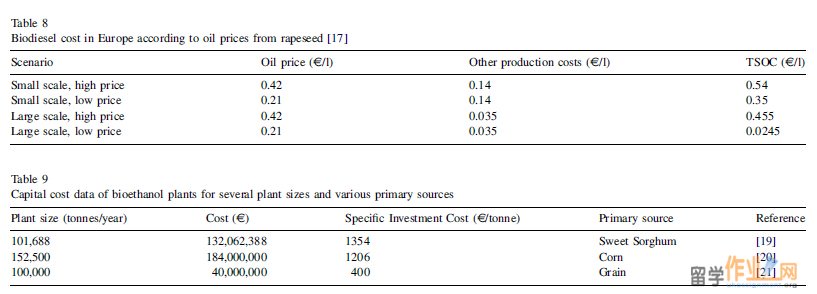

Total Specific Investment Cost of biodiesel production plants as a function of their size [14] Plant size (tonnes/year) Low automation High automation Investment Cost (s) Specific Investment Cost (s/tonne) Investment Cost (s) Specific Investment Cost (s/tonne) 3,520 52,800 132,000 1,500,000 7,480,315 15,511,811 374 124 103 2,440,945 12,440,945 25,926,771 610 207 172 Regarding the operating cost of biodiesel production, it is considered, first of all, that the primary sources cost represents usually the 60–80% of the Total Specific Operating Cost (TSOC expressed as s/l biodiesel) of these plants [16].The economical feasibility of biodiesel plants is also linked with the selling possibility of glycerine which is provided as by-product. For a biodiesel plant of 150,000 tonnes/year capacity, the rest of the operating costs, except for the primary sources cost, represent a percentage of 7–15% of the TSOC. An example of the cost of biodiesel production is provided at Table 8 which represents various scenarios for oil produced from oil containing seeds (rapeseeds are used as primary source).

5.3. Bioethanol plants

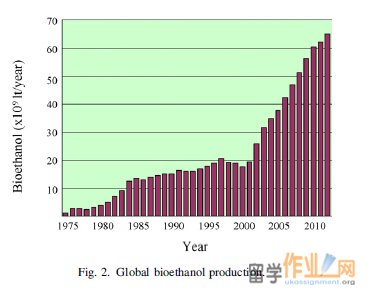

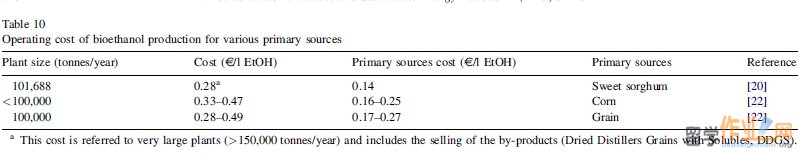

The total global bioethanol production (transportation fuel with a production as high as 40 109 l/year), is presented in Fig. 2 [18]. The main bioethanol producer country is Brazil (since 1976, the programme Proalcool is in operation). The investment cost of bioethanol units is linked with many parameters the most significant of which are the following: the primary sources type and more specifically if they are: (a) saccharate primary sources (conventional, e.g. beet and sugar cane, or new, energy crops, e.g. sweet sorghum); (b) grains (wheat or corn); (c) or lignine-cellulosic primary sources (up to now the relevant technology is under investigation). the size of the plants and the possibility to achieve economies-of-scale;

Table 8 Biodiesel cost in Europe according to oil prices from rapeseed [17] Fig.2.Globalbioethanolproduction. the possibility to use also other organic residues (e.g. the woody part of sweet sorghum or corn), for covering large energetic needs of the bioethanol production plant. Some data of the Investment Cost for several plant sizes and various primary sources are presented in Table 9. From the above mentioned data, a wide range concerning the SIC can be observed. This should not be normally expected, due to the fact that alcoholic fermentation is a mature technology. The high cost when using sweet sorghum is linked with the fact that also the technological risks are included when using this specific primary source. Furthermore, it should be mentioned that in the case of the specific plant, the realization of the whole production plant has been taken into consideration. This Scenario Oil price (s/l) Other production costs (s/l) TSOC (s/l) Small scale, high price Small scale, low price Large scale, high price Large scale, low price 0.42 0.21 0.42 0.21 0.14 0.14 0.035 0.035 0.54 0.35 0.455 0.0245 Table 9 Capital cost data of bioethanol plants for several plant sizes and various primary sources Plant size (tonnes/year) Cost (s) Specific Investment Cost (s/tonne) Primary source Reference 101,688 152,500 100,000 132,062,388 184,000,000 40,000,000 1354 1206 400 Sweet Sorghum Corn Grain [19] [20] [21]

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

Table 10 Operating cost of bioethanol production for various primary sources Plant size (tonnes/year) Cost (s/l EtOH) Primary sources cost (s/l EtOH) Primary sources Reference 101,688 <100,000 100,000 0.28a 0.33–0.47 0.28–0.49 0.14 0.16–0.25 0.17–0.27 Sweet sorghum Corn Grain [20] [22] [22] a This cost is referred to very large plants (>150,000 tonnes/year) and includes the selling of the by-products (Dried Distillers Grains with Solubles, DDGS). includes also the additional investments (e.g. electricity production, cattle feed, pellets production, etc.). The cost provided by GEA Wiegand is very low and eventually does not include these additional parts of the process (like for example the energy recovery part). According to the operating programme ‘‘competitiveness’’ of the Greek Ministry of Development [15], the selected Investment Cost for a production unit with a capacity of 100,000 tonnes bioethanol/year, is s50,000,000 (it considers as SIC the price of s500 tonne 1. That means that it is closer to the estimation of the company GEA Wiegand [21]. The operating cost of bioethanol production plants, is presented in Table 10. The bioethanol production cost is, generally, higher in Europe than in USA. This is mainly due to the high production cost of primary sources in Europe, but also to the low energy cost in USA.

5.4. Power production plants from solid biomass

As presented by Boukis [12] the Specific Investment Cost for an electricity production unit of an installed capacity higher than 12 MWe does not change significantly with the plant size. Therefore the Specific Investment Cost of these plants is well approximated to s 1650 kWe 1. The fuel cost at the gate of the unit has a share of about 37% of the total operating cost of the unit or 40% of the TOC if the annuity is not taken into consideration. These are the figures in the case of biomass feeding with residues. In the case of feeding of the plant with energy crops (fiber sorghum) it is expected that the fuel cost for the feeding of these plants (including the transportation and pre-treatment cost, according to Table 5) will be higher. If the economies-of-scale are taken into consideration, the reduction of operating cost (apart from the fuel cost) is expected to be even higher.

5.5. Central Digestion Units

The total operating costs of Central Digestion Units of organic residues depends on their daily potential (organic waste input every day). For a unit of 150–200 tonnes/day (or 50,000 tonnes/year, for an availability of 90%), the TOC ranges between s2,500,000 and 5,000,000, depending on the type of the unit: Whether the unit is of agricultural type, low automation and provides the produced biogas to neighbouring exploitation units (this model is widely spread in Germany, Denmark and Sweden), or whether it has an autonomous and high automation electricity production system (if, for example, it is able to receive other organic waste). The cost of the digestion units depends mainly on the operating and maintenance cost, which is usually presented as a percentage of the Investment Cost and ranges between 3 and 5% of this cost [23]. The feasibility of these units depends on the revenue coming from treatment of organic waste (minimization of the pollution) and, secondly, on the selling of the produced electricity and heat, but also on the provision of the compost. #p#分页标题#e#

6. Economic viability of the examined conversion plants and discussion about the profit of the farmers 检查转化厂和对农民的利益讨论的经济可行性

The aim of this chapter is to describe the profitable investment plants for biomass conversion and to discuss the additional subsidy needed for the producers of primary biomass. The results presented here are based on the methodology and the biomass data presented in the first part of this article. More specifically, following data has been presented up to now: (a) The needed cultivation areas and the types of energy crops that are expected to be exploited in order to reach the aims of Greece until 2010. (b) An estimation concerning the technically usable biomass potential, when conventional cultivations are being replaced, has been done. The cultivation area for their production has been estimated, as well as typical size of units for the conversion of primary biomass into final products (liquid biofuels (biodiesel and bioethanol), electrical power, solid fuels (pellets)). (c) Some specific areas in Greece have been detected, where it is technically possible to feed the conversion plants with the products of the relevant energy crops. (d) The fluctuation of the range of investment and operating cost for typical sizes of biomass conversion plants has been discussed. Two main conditions are needed for the viability of bioconversion projects and concern both sides, first of all the investors (responsible for the realization and the operation of the bioconversion units) and the farmers-producers (providers of the primary sources in the conversion units): (a) The farmers should at least retain their net profit at the same level as it is nowadays with conventional cultivations, if they replace them with energy crops.

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 (b) The investors should have a minimum percentage of profit, which is expressed with the Internal Rate of Return (IRR) and is set equal to 15%.

6.1. Methodology for the calculation of the Net Future Profit

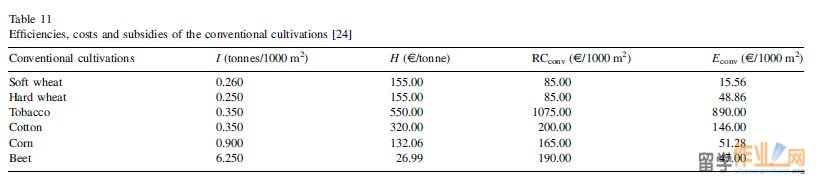

(NFP) for the farmers-producers For the calculation of the Net Future Profit of the farmers-producers, after the introduction of energy crops, which can replace conventional (traditional) cultivations, two figures have to be calculated: -the production cost of primary sources, both for energy crops and conventional cultivations; -the present and future total subsidies for conventional and energy crops cultivations respectively. For the calculation of the production cost of primary sources and the needed subsidy to the farmers the methodology which can be used is described as follows: Following parameters are set: A: The purchasing cost of the primary source (s/1000 m2), which corresponds to the Maximum Acceptable Purchasing Fuel Price (MAPFP, see D) of this specific primary source. B: The field efficiency of the primary source (tonnes/ 1000 m2). C: The transportation cost of the primary source (s/tonne). a%: The percentage of the primary source losses in the supply chain (assumption: a quantity of 2a/3 is lost in the field during mowing/collection and chipping and a/3 is lost during transportation). D: The Maximum Acceptable Purchasing Fuel Price (MAPFP) of the primary source in the gate of the bioconversion unit. All calculations are referred to 1 tonne of primary source (energy crop) produced in the field. Therefore: 1 tonne in the field costs: (A/B)(s); the transportation costs: C (s/tonne) 1 tonne (1 2a/ 3) = (1 2a/3)C (s); the final cost up to the gate of the plant is: (A/B)+(1 2a/ 3)C (s); the final purchasing cost at the gate of the plant (s/tonne) is calculated from Eq. (2): eA=BTte1 2a=3TC D . (2)1 a The relation between the primary source production in the field and the MAPFP is provided using Eq. (3): . . 2a A .e1 aTD 1 C B (3)3 Taken into consideration that the efficiency of the supply chain is around 70% (a = 30%), Eq. (3) can be written as follows: A ..0:7 D 0:8 C B (4) Some further parameters needed are: RCconv: The real cost of the conventional cultivation that is about to be replaced with energy crops (s/1000 m2). RCen: The real production cost of the energy crop (s/ 1000 m2). Econv: The present subsidy for the conventional cultivation (s/1000 m2). Een: The needed subsidy for the energy crops cultivation, in order to ensure the same profit for the farmer as the one he has with the present conventional cultivations (s/ 1000 m2). H: The present selling price of the conventional cultivation in the delivery point (s/tonne). I: The area efficiency of the conventional cultivation (tonne/1000 m2). b%: The losses of the product in the conventional cultivation at the supply chain (b 20%). Using these parameters, the Net Present Profit (NPP) and the Net Future Profit of the farmer are calculated as follows: NPP .Econv tH I e1 bT RCconv (5) NFP .Een teA RCenT (6) As discussed before the two profits have to be at least equal (NPP = NFP), therefore, the additional needed subsidy

(differ-Table 11 Efficiencies, costs and subsidies of the conventional cultivations [24] Conventional cultivations I (tonnes/1000 m2) H (s/tonne) RCconv (s/1000 m2) Econv (s/1000 m2) Soft wheat 0.260 155.00 85.00 15.56 Hard wheat 0.250 155.00 85.00 48.86 Tobacco 0.350 550.00 1075.00 890.00 Cotton 0.350 320.00 200.00 146.00 Corn 0.900 132.06 165.00 51.28 Beet 6.250 26.99 190.00 47.00

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

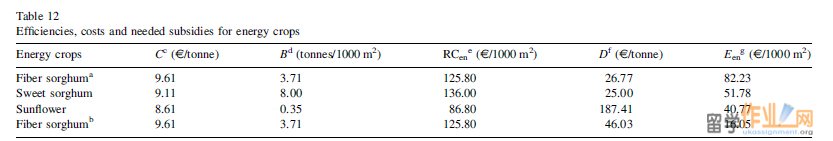

Table 12 Efficiencies, costs and needed subsidies for energy crops Energy crops Cc (s/tonne) Bd (tonnes/1000 m2) RCen (s/1000 m2) Df (s/tonne) Een g (s/1000 m2) Fiber sorghuma Sweet sorghum Sunflower Fiber sorghumb 9.61 9.11 8.61 9.61 3.71 8.00 0.35 3.71 125.80 136.00 86.80 125.80 26.77 25.00 187.41 46.03 82.23 51.78 40.77 16.05 a Fiber sorghum for electricity production units. b Fiber sorghum for biomass treatment and conversion units. c Data from Table 5. d Data as discussed in Section 2.2 [3]. e Data from Tables 2 and 3. f These figures will be discussed in Sections 6.2–6.5. g These figures will be discussed in Sections 6.2–6.5. ential subsidy) is calculated from Eq. (7) DE .Een Econv . eRCconv RCenTte1 0:2T eH IT A (7) The production costs taking into consideration the present subsidies are presented in Tables 11 and 12. Given that for every conventional cultivation all the parameters of Eq. (7) are known, only the Maximum Acceptable Purchasing Fuel Price (MAPFP = D) is needed in order to calculate the ‘‘Energy crops’’subsidy (Een). This figure (MAPFP) is provided from the economic analysis of each conversion unit.

6.2. Fiber sorghum fired power unit ( 15 MWe)

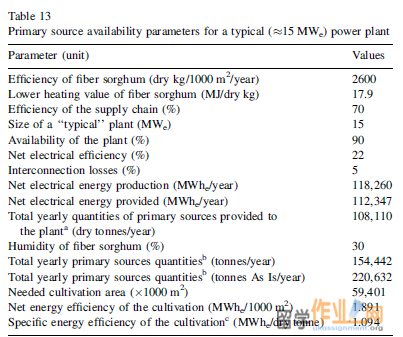

For a typical power unit (15 MWe) with fiber sorghum as primary source, the main parameters concerning the fuel are presented in Table 13.

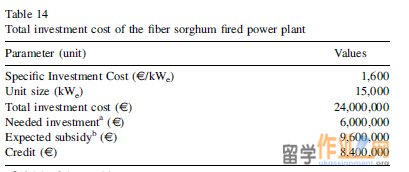

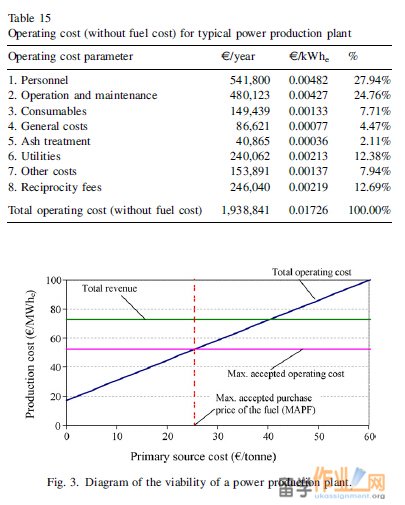

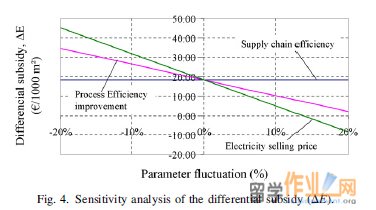

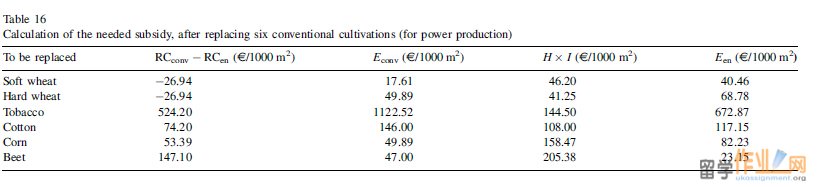

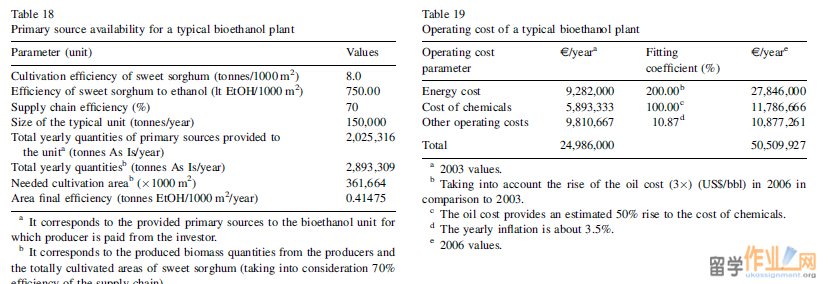

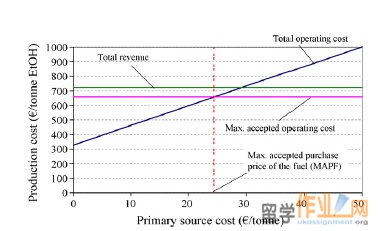

Table 13 Primary source availability parameters for a typical ( 15 MWe) power plant Parameter (unit) Values Efficiency of fiber sorghum (dry kg/1000 m2/year) 2600 Lower heating value of fiber sorghum (MJ/dry kg) 17.9 Efficiency of the supply chain (%) 70 Size of a ‘‘typical’’ plant (MWe) 15 Availability of the plant (%) 90 Net electrical efficiency (%) 22 Interconnection losses (%) 5 Net electrical energy production (MWhe/year) 118,260 Net electrical energy provided (MWhe/year) 112,347 Total yearly quantities of primary sources provided to 108,110 the planta (dry tonnes/year) Humidity of fiber sorghum (%) 30 Total yearly primary sources quantitiesb (tonnes/year) 154,442 Total yearly primary sources quantitiesb (tonnes As Is/year) 220,632 Needed cultivation area ( 1000 m2) 59,401 Net energy efficiency of the cultivation (MWhe/1000 m2) 1.891 Specific energy efficiency of the cultivationc (MWhe/dry tonne) 1.094 a It corresponds to the provided primary sources to the power unit for which the producer is paid from the investor. b It corresponds to the produced biomass quantities from the producers and the totally cultivated surfaces of fiber sorghum (taking into consideration 70% efficiency of the supply chain). c It corresponds to the energetic efficiency of the primary sources provided to the unit. The total investment cost and the financing of the plant is presented in Table 14. The operating cost for a 15 MWe unit (excluding the fuel cost) is presented in Table 15 based on previous studies [25]. According to the Greek law (N. 3468/2006) the selling price of electricity to the net is s73 MWhe 1. Using the above mentioned data, according to Eq. (4) and considering the minimum IRR of 15%, the MAPFP of this scenario is s25.44 tonne 1. In order to have a desirable economic efficiency, the purchasing cost of the fiber sorghum in the field cannot exceed the value of A = s37.60/1000 m2. Fig. 3 presents the viability of the specific investment plan. Furthermore, according to the production cost of fiber sorghum (Table 3) and the conventional cultivations [24], the results provided by Eq. (7) are presented in Table 16. In Table 16 it can be seen that the needed subsidy depends on the replaced conventional cultivation. It is also possible to calculate the differential subsidy DE, if a cultivation area of 59,401 1000 m2 (see Table 13) is replaced. The results are presented in Table 17. In Table 17 it can be seen that in order to retain their present profit, farmers should: -get higher subsidy in the cases of soft and hard wheat, corn and beet; -get lower subsidy in the cases in which tobacco or cotton cultivations are being replaced. Finally, Fig. 4 shows the sensitivity analysis of the differential subsidy as a function of three parameters (efficiency Table 14 Total investment cost of the fiber sorghum fired power plant Parameter (unit) Values Specific Investment Cost (s/kWe) 1,600 Unit size (kWe) 15,000 Total investment cost (s) 24,000,000 Needed investmenta (s) 6,000,000 Expected subsidyb (s) 9,600,000 Credit (s) 8,400,000 a 25% of the total investment cost. b 40% of the total investment cost. #p#分页标题#e#

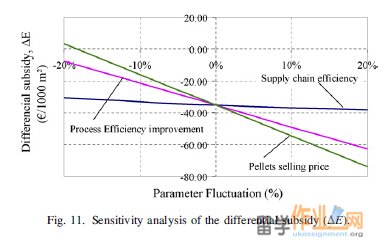

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 Table 15 Operating cost (without fuel cost) for typical power production plant Operating cost parameter s/year s/kWhe % 1. Personnel 541,800 0.00482 27.94% 2. Operation and maintenance 480,123 0.00427 24.76% 3. Consumables 149,439 0.00133 7.71% 4. General costs 86,621 0.00077 4.47% 5. Ash treatment 40,865 0.00036 2.11% 6. Utilities 240,062 0.00213 12.38% 7. Other costs 153,891 0.00137 7.94% 8. Reciprocity fees 246,040 0.00219 12.69% Total operating cost (without fuel cost) 1,938,841 0.01726 100.00% Fig.3.Diagramoftheviabilityofapowerproductionplant.of the supply chain, improvement of the efficiency of the power generation process, price of electricity sold to the net). From this figure it can be seen that, if the efficiency of the supply chain improves 10% (from 70 to 77%), the differential subsidy is practically constant at s18.29/1000 m2. If there is a 10% rise

Table 16 Fig.4.Sensitivityanalysisofthedifferentialsubsidy(DE).of the selling price of electricity (from s73.00 to 80.30 MWhe 1), the needed differential subsidy is lower (from s18.29 to 4.96/1000 m2). Finally, if the efficiency of power generation is 10% higher (from 22 to 24.2% by using a more effective combustion chamber), the needed differential subsidy is lower (from s18.29 to 10.18/1000 m2). The improvement of the three parameters can reduce the needed differential subsidy to (0 + 13.33 + 8.11=)s21.44/ 1000 m2. This subsidy can make the fiber sorghum fuelled power production plants feasible.

6.3. Bioethanol plant (150,000 tonnes/year) using sweet sorghum as primary source

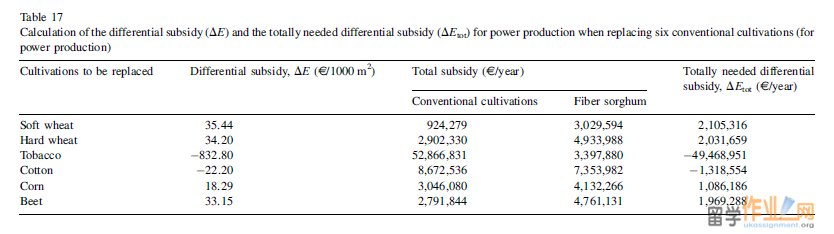

For a typical plant of bioethanol production (capacity 150,000 tonnes/year) using sweet sorghum as primary source, the main parameters concerning the availability of primary source are presented in able 18. Calculation of the needed subsidy, after replacing six conventional cultivations (for power production) To be replaced RCconv RCen (s/1000 m2) Econv (s/1000 m2) H I (s/1000 m2) Een (s/1000 m2) Soft wheat Hard wheat Tobacco Cotton Corn Beet 26.94 26.94 524.20 74.20 53.39 147.10 17.61 49.89 1122.52 146.00 49.89 47.00 46.20 41.25 144.50 108.00 158.47 205.38 40.46 68.78 672.87 117.15 82.23 23.15 Table 17 Calculation of the differential subsidy (DE) and the totally needed differential subsidy (DEtot) for power production when replacing six conventional cultivations (for power production) Cultivations to be replaced Differential subsidy, DE (s/1000 m2) Total subsidy (s/year) Totally needed differential subsidy, DEtot (s/year) Conventional cultivations Fiber sorghum Soft wheat 35.44 924,279 3,029,594 2,105,316 Hard wheat 34.20 2,902,330 4,933,988 2,031,659 Tobacco 832.80 52,866,831 3,397,880 49,468,951 Cotton 22.20 8,672,536 7,353,982 1,318,554 Corn 18.29 3,046,080 4,132,266 1,086,186 Beet 33.15 2,791,844 4,761,131 1,969,288

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

Table 18 Primary source availability for a typical bioethanol plant Parameter (unit) Values Cultivation efficiency of sweet sorghum (tonnes/1000 m2) 8.0 Efficiency of sweet sorghum to ethanol (lt EtOH/1000 m2) 750.00 Supply chain efficiency (%) 70 Size of the typical unit (tonnes/year) 150,000 Total yearly quantities of primary sources provided to 2,025,316 the unita (tonnes As Is/year) Total yearly quantitiesb (tonnes As Is/year) 2,893,309 Needed cultivation areab ( 1000 m2) 361,664 Area final efficiency (tonnes EtOH/1000 m2/year) 0.41475 a It corresponds to the provided primary sources to the bioethanol unit for which producer is paid from the investor. b It corresponds to the produced biomass quantities from the producers and the totally cultivated areas of sweet sorghum (taking into consideration 70% efficiency of the supply chain). The investment cost of a typical bioethanol unit, according to the literature, is as follows: The Greek Ministry of Development [15] sets the specific cost equal to s500 tonne 1, so the maximum selected cost of the unit should be (500 150,000=)s75,000,000. Tiffany and Eidman [26] set the investment cost of a bioethanol plant from corn, of similar capacity (154,379 tonnes/year) equal to US$ 78,000,000 (referred to the prices in 2003), therefore, the specific cost is US$ 0.4 l 1. With a mean inflation of 3%, the specific cost is in 2006 US$ 0.44 l 1 or (s1 = US$ 1.25) s0.35 l 1. The study of the European Beet Growers’ Association [27], provides a specific cost of European bioethanol units of similar capacity (from 120,000 to 170,000 tonnes/year) at a price range of s0.4–0.8 l 1 (mean value s0.6 l 1). In the present study, as specific cost of a 150,000 tonnes/year bioethanol unit, the mean value of the USA (s0.35/l) and the EU (s0.6/l) will be used, after the addition of 15% due to the additional alterations and the longer time needed for the start of the unit to efficient production using sweet sorghum {(0.35 + 0.60)/2} 115% s0.55 l 1 or (for a bioethanol density of 0.79 kg/l) s690 tonne 1. Therefore the investment cost of a typical bioethanol unit is estimated at around s103,500,000. The operating cost is presented in Table 19 based on data from Tiffany and Eidman [26]. According to the above, the Specific Operating Cost (SOC) excluding the Fuel Cost (FC) of a typical biomass is equal to: s50; 509; 927 year 1 SOC FC .. s327 tonne 1 EtOH 154; 379 tonnes=year The transportation and pre-treatment cost of sweet sorghum is estimated at s9.11 tonne 1 (see Table 5). According to the data of Elobeid and Tokgoz [28], the average selling price of bioethanol (according to USA and Brazil data) is about s500 tonne 1 and of DDGS is according Tiffany and Eidman [26] s74 tonne 1 EtOH (the prices are related to 2006). According to the study CIBE [27] the average Table 19 Operating cost of a typical bioethanol plant Operating cost parameter s/yeara Fitting coefficient (%) s/yeare Energy cost Cost of chemicals Other operating costs 9,282,000 5,893,333 9,810,667 200.00b 100.00c 10.87d 27,846,000 11,786,666 10,877,261 Total 24,986,000 50,509,927 a 2003 values. b Taking into account the rise of the oil cost (3 ) (US$/bbl) in 2006 in comparison to 2003. c The oil cost provides an estimated 50% rise to the cost of chemicals. d The yearly inflation is about 3.5%. e 2006 values. selling price of bioethanol in the European Union is estimated at around s700 tonne 1. For secure calculations, the selling price of bioethanol in the present study is considered to be s650 tonne 1. The above data is inserted to a typical economic model where it is calculated that the MAPFP in this scenario is equal to s24.40 tonne 1. The viability of the specific investment plan is presented in Fig. 5. Since MAPFP is calculated and considering the efficiency data (Table 2) and the transportation cost of sweet sorghum (Table 5), it is calculated that, according to Eq. (4) in order to have an IRR = 15%, the procurement cost of sweet sorghum from the field cannot exceed the price of A = s78.33/1000 m2. Based on the data for the production of sweet sorghum (Table 2) and the cultivations to be replaced (Table 11) the needed subsidy (Een) is calculated from Eq. (7) and presented in Table 20. In Table 20 it can be seen that the needed subsidy is lower than the present one in the cases of tobacco, cotton and corn and higher for the other cultivations. It is also possible to calculate the differential subsidy DE, if a cultivation area of 361,644 1000 m2 (see Table 18) is replaced. The results are presented in Table 21. From the data in Table 21 it can be seen that in the case of tobacco, cotton and corn, the differential subsidy is negative, that means that no additional subsidy is needed. Finally, Fig. 6 presents the sensitivity analysis of the differential subsidy as a function of three parameters (efficiency Fig.5.Diagramoftheviabilityofabioethanolplant.

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

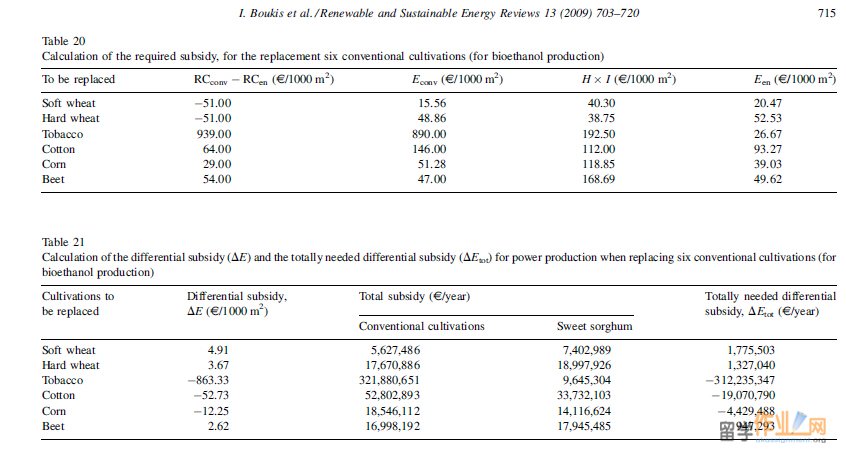

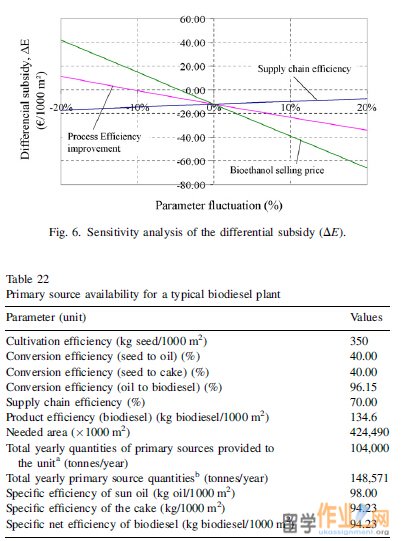

Table 20 Calculation of the required subsidy, for the replacement six conventional cultivations (for bioethanol production) To be replaced RCconv RCen (s/1000 m2) Econv (s/1000 m2) H I (s/1000 m2) Een (s/1000 m2) Soft wheat Hard wheat Tobacco Cotton Corn Beet 51.00 51.00 939.00 64.00 29.00 54.00 15.56 48.86 890.00 146.00 51.28 47.00 40.30 38.75 192.50 112.00 118.85 168.69 20.47 52.53 26.67 93.27 39.03 49.62 Table 21 Calculation of the differential subsidy (DE) and the totally needed differential subsidy (DEtot) for power production when replacing six conventional cultivations (for bioethanol production) Cultivations to Differential subsidy, Total subsidy (s/year) Totally needed differential be replaced DE (s/1000 m2) subsidy, DEtot (s/year) Conventional cultivations Sweet sorghum Soft wheat 4.91 5,627,486 7,402,989 1,775,503 Hard wheat 3.67 17,670,886 18,997,926 1,327,040 Tobacco 863.33 321,880,651 9,645,304 312,235,347 Cotton 52.73 52,802,893 33,732,103 19,070,790 Corn 12.25 18,546,112 14,116,624 4,429,488 Beet 2.62 16,998,192 17,945,485 947,293 of the supply chain, improving of the efficiency of the process, selling price of bioethanol). From this figure it can be seen that for 10% rise of the selling price of bioethanol (from s650 to 715 tonne 1) the needed differential subsidy is decreasing from s 12.25 to 39.02/1000 m2. Furthermore, if there is a process efficiency increase of 10% (e.g. with the development of more efficient enzymes) the needed differential subsidy decreases from s 12.25 to 23.61/1000 m2. If, finally, there is a 10% increase in the efficiency of the supply chain (from 70 to 77%), the needed differential subsidy increases from s 12.25 to 9.91/1000 m2. The improvement of the first two parameters, reduces the differential subsidy to (26.77 + 11.36=)s38.13/1000 m2. Therefore, no subsidy is needed for the production of bioethanol. #p#分页标题#e#

6.4. Biodiesel plant (40,000 tonnes/year) using sunflower as primary source

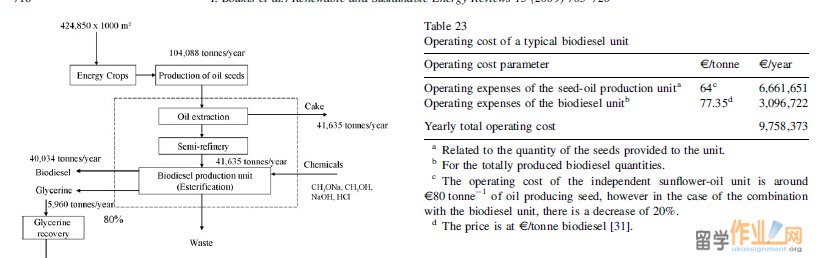

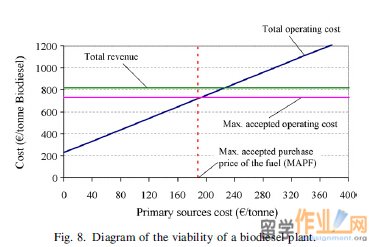

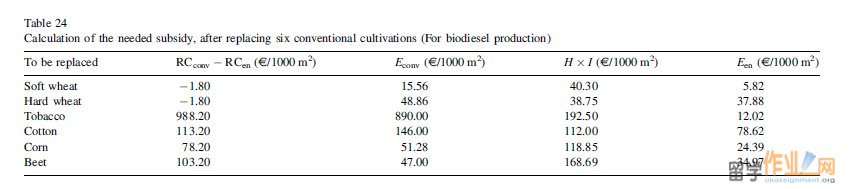

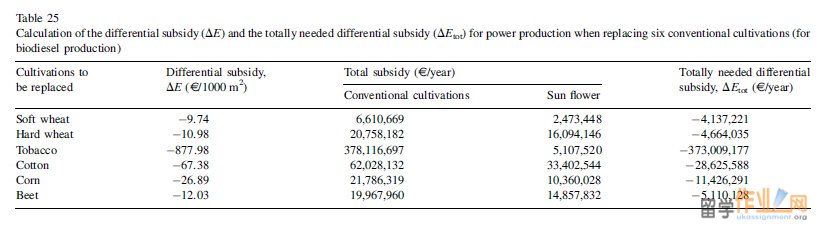

For a typical plant of biodiesel production (capacity 40,000 tonnes/year) using sunflower as primary source, the main parameters concerning the availability of primary source are presented in Table 22. Fig. 7 represents schematically a biodiesel production unit which includes the seed-oil conversion unit (extraction of gross oil), the semi-refinery (where the neutralization of the gross oil takes place) and the biodiesel unit (where the esterisation of the neutralized oil with methanol takes place). This production direction is followed by a lot of investment plans in Greece for biodiesel production. It should be remarked that the produced glycerine (by-product of the unit) has an 80% purity and is provided to the glycerine market (cosmetics, soap Fig. 6. Sensitivity analysis of the differential subsidy (DE). Table 22 Primary source availability for a typical biodiesel plant Parameter (unit) Values Cultivation efficiency (kg seed/1000 m2) 350 Conversion efficiency (seed to oil) (%) 40.00 Conversion efficiency (seed to cake) (%) 40.00 Conversion efficiency (oil to biodiesel) (%) 96.15 Supply chain efficiency (%) 70.00 Product efficiency (biodiesel) (kg biodiesel/1000 m2) 134.6 Needed area ( 1000 m2) 424,490 Total yearly quantities of primary sources provided to 104,000 the unita (tonnes/year) Total yearly primary source quantitiesb (tonnes/year) 148,571 Specific efficiency of sun oil (kg oil/1000 m2) 98.00 Specific efficiency of the cake (kg/1000 m2) 94.23 Specific net efficiency of biodiesel (kg biodiesel/1000 m2) 94.23 a It corresponds to the provided primary sources to the biodiesel unit for which producer is paid from the investor. b It corresponds to the produced biomass quantities from the producers and the totally cultivated area of sunflowers for biodiesel (taking into consideration 70% efficiency of the supply chain).

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 Fig.7.Schemeofabiodieselproductionunitfromsunflower.production, etc.). The non-treated glycerine can also be used in Central Digestion Units. The selling price of the non-treated glycerine (crude glycerine) shows a great fluctuation. More specifically, the prices ranged from s340 tonne 1 in June 2004 to s190 tonne 1 in January 2005, due to the high biodiesel production in Europe. The prices are expected to be stabilized to the level of s200 tonne 1 of pure glycerine (efficiency 80%) [29]. The investment cost of a typical biodiesel production unit is calculated as follows: -For the biodiesel unit (electrical and mechanical equipment) the Specific Investment Cost is estimated at s 570 tonne 1 biodiesel/year, or the total investment cost is (570 40,034=)s22,820,000. -For the seed-oil conversion unit and the semi-refinery (electrical and mechanical equipment), the Specific Investment Cost is estimated at s 100 tonne 1 of oil producing seeds/year [30], or the total investment cost is (100 104,088=)s10,409,000. -For the civil engineering costs and the other costs (energy potential studies, consultancy, etc.) the investment cost is estimated at 12 and 2%, respectively, to the total investment cost of the electrical and mechanical equipment cost (about s4,000,000 and 700,000, respectively). The total investment cost of the whole unit is around s38,000,000. The needed investment is estimated at 25% and the possible subsidy at 40%.

Table 23 Operating cost of a typical biodiesel unit Operating cost parameter s/tonne s/year Operating expenses of the seed-oil production unita 64c 6,661,651 Operating expenses of the biodiesel unitb 77.35d 3,096,722 Yearly total operating cost 9,758,373 a Related to the quantity of the seeds provided to the unit. b For the totally produced biodiesel quantities. c The operating cost of the independent sunflower-oil unit is around s80 tonne 1 of oil producing seed, however in the case of the combination with the biodiesel unit, there is a decrease of 20%. d The price is at s/tonne biodiesel [31]. Fig.8.Diagramoftheviabilityofabiodieselplant.The operating cost (without fuel cost) of a typical biodiesel unit is presented in Table 23. The operating cost of the seed-oil (without fuel cost) is estimated at s 75–85 tonne 1 of oil producing seeds [30]. However, due to the combination of the oil production unit and the biodiesel unit it is expected that this cost will be reduced at around 20% due to economies of scale. As mentioned before, the prices of the products and byproducts are for biodiesel s 650 tonne 1 biodiesel [4] for cake s 150 tonne 1 cake [32] and for glycerine s200 tonne 1 of pure glycerine. The above data is inserted to a typical economic model where it is calculated that the MAPFP in this scenario is equal to s188.53 tonne 1. The viability of the specific investment plan is presented in Fig. 8. Since MAPFP is calculated and considering the efficiency data (Table 1) and the transportation cost of sunflower (Table 5), it is calculated that, according to Eq. (4), in order to have an IRR = 15%, the procurement cost of sunflower from the field cannot exceed the price of A = s43.78/1000 m2. Table 24 Calculation of the needed subsidy, after replacing six conventional cultivations (For biodiesel production) To be replaced RCconv RCen (s/1000 m2) Econv (s/1000 m2) H I (s/1000 m2) Een (s/1000 m2) Soft wheat 1.80 15.56 40.30 5.82 Hard wheat 1.80 48.86 38.75 37.88 Tobacco 988.20 890.00 192.50 12.02 Cotton 113.20 146.00 112.00 78.62 Corn 78.20 51.28 118.85 24.39 Beet 103.20 47.00 168.69 34.97

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

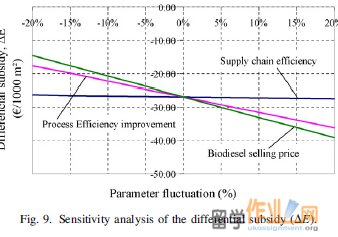

Table 25 Calculation of the differential subsidy (DE) and the totally needed differential subsidy (DEtot) for power production when replacing six conventional cultivations (for biodiesel production) Cultivations to be replaced Differential subsidy, DE (s/1000 m2) Total subsidy (s/year) Conventional cultivations Sun flower Totally needed differential subsidy, DEtot (s/year) Soft wheat Hard wheat Tobacco Cotton Corn Beet 9.74 10.98 877.98 67.38 26.89 12.03 6,610,669 20,758,182 378,116,697 62,028,132 21,786,319 19,967,960 2,473,448 16,094,146 5,107,520 33,402,544 10,360,028 14,857,832 4,137,221 4,664,035 373,009,177 28,625,588 11,426,291 5,110,128 Based on the data for the production of sunflower (Table 1) and the cultivations to be replaced (Table 11) the needed subsidy (Een) is provided in Table 24. Table 24 shows that the needed subsidy Een is lower than the present subsidy for all cultivations. The differential subsidy for total sunflower cultivation area of 424,490 1000 m2 is presented in Table 25. It can be seen that in all cases a negative differential subsidy appears. So lower subsidies are needed in the case in which the conventional cultivations are replaced with sunflowers. Finally, Fig. 9 shows the sensitivity analysis of the differential subsidy as a function of three parameters (efficiency of the supply chain, improving of the efficiency of the process (oil production), selling price of biodiesel). From this figure it can be seen that if the selling price of biodiesel increases 10% (from s650 to 715 tonne 1), the differential subsidy decreases from s 26.89 to 33.00/ 1000 m2. If the process efficiency increases 10% (efficiency of the seed to oil from 40 to 44%), the differential subsidy decreases from s 26.89 to 31.49/1000 m2. Finally if the efficiency of the supply chain increases 10% (from 70 to 77%) the needed differential subsidy decreases only moderate (from s 26.89 to 27.11 tonne 1). The improvement of the first two parameters (of the biodiesel price and the efficiency of the process), leads to a total decrease of the differential subsidy of sunflower, around (6.11 + 4.60=) s10.71/1000 m2, making the combined units of oil and biodiesel production from sunflower feasible. Fig.9.Sensitivityanalysisofthedifferentialsubsidy(DE).

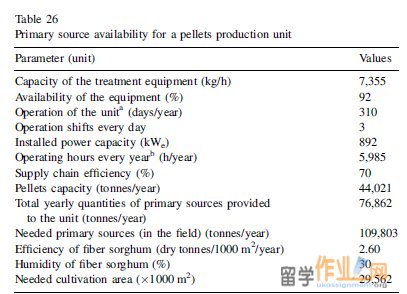

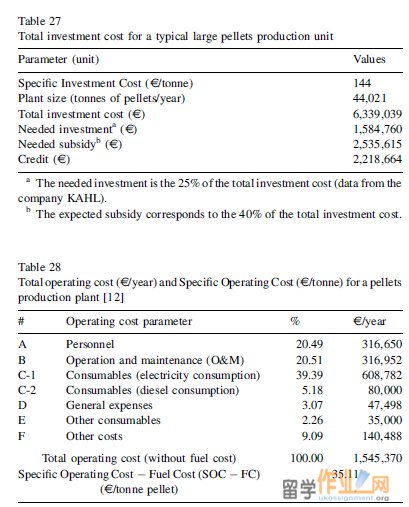

6.5. Pellet production unit ( 44,000 tonnes/year) from fiber sorghum

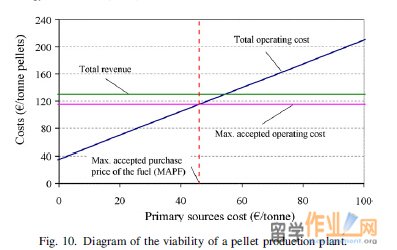

For a typical unit of pellet production (capacity 44,000 tonnes/year) using fiber sorghum as primary source, the main parameters concerning the availability of primary source are presented in Table 26. The data is based on information from the German pellet company KAHL [33] for a unit of similar capacity [12]. Tables 27 and 28 present the total investment cost as well as the operating cost for the pellet unit. Thek and Obernberger [34] present a SOC-FC of around s45 tonne 1 for a unit of a capacity of 24,000 tonnes of pellets a year. The present approach, regarding also the capacity difference of the two units is satisfactory. In central Europe, the selling price of pellets is around s170 tonne 1. This price is given in mature markets (Germany, Austria), where there is a supply and selling system of the pellets and a high demand but also technical support for pellet fired boilers. Therefore it is expected that the starting pellet price in Greece will be much lower and after some years it will reach the level of central Europe. In the present study a selling price of s130 tonne 1 is set. The above data is inserted to a typical economic model and the MAPFP in this scenario is calculated equal to

#p#分页标题#e# #p#分页标题#e#Table 26 Primary source availability for a pellets production unit Parameter (unit) Values Capacity of the treatment equipment (kg/h) 7,355 Availability of the equipment (%) 92 Operation of the unita (days/year) 310 Operation shifts every day 3 Installed power capacity (kWe) 892 Operating hours every yearb (h/year) 5,985 Supply chain efficiency (%) 70 Pellets capacity (tonnes/year) 44,021 Total yearly quantities of primary sources provided 76,862 to the unit (tonnes/year) Needed primary sources (in the field) (tonnes/year) 109,803 Efficiency of fiber sorghum (dry tonnes/1000 m2/year) 2.60 Humidity of fiber sorghum (%) 30 Needed cultivation area ( 1000 m2) 29,562 a Week operation of the unit with the exception of Sundays and very important holidays (except 55 days a year). b 7 working hours in each shift.

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720

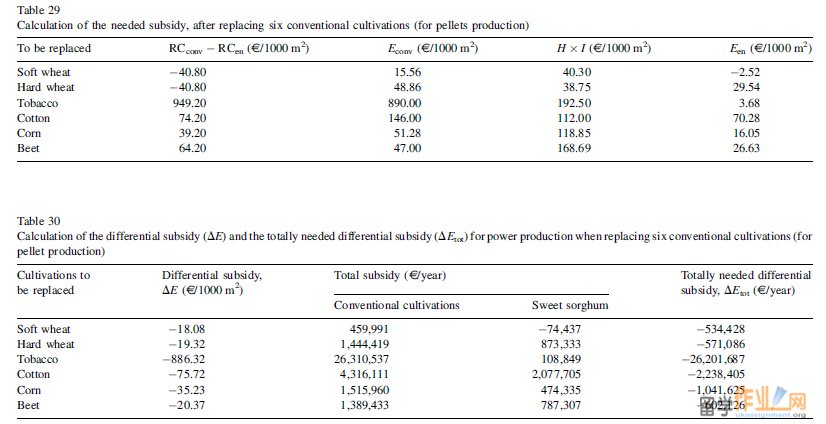

Table 27 Total investment cost for a typical large pellets production unit Parameter (unit) Values Specific Investment Cost (s/tonne) 144 Plant size (tonnes of pellets/year) 44,021 Total investment cost (s) 6,339,039 Needed investmenta (s) 1,584,760 Needed subsidyb (s) 2,535,615 Credit (s) 2,218,664 a The needed investment is the 25% of the total investment cost (data from the company KAHL). b The expected subsidy corresponds to the 40% of the total investment cost. Table 28 Total operating cost (s/year) and Specific Operating Cost (s/tonne) for a pellets production plant [12] # Operating cost parameter % s/year A Personnel 20.49 316,650 B Operation and maintenance (O&M) 20.51 316,952 C-1 Consumables (electricity consumption) 39.39 608,782 C-2 Consumables (diesel consumption) 5.18 80,000 D General expenses 3.07 47,498 E Other consumables 2.26 35,000 F Other costs 9.09 140,488 Total operating cost (without fuel cost) 100.00 1,545,370 Specific Operating Cost Fuel Cost (SOC FC) 35.11 (s/tonne pellet) s46.03 tonne 1. The viability of the specific investment plan is presented in Fig. 10. Since MAPFP is calculated and considering the efficiency data (Table 3) and the transportation cost of fiber sorghum (Table 5), it is calculated that, according to Eq. (4) in order to Table 29 Fig. 10. Diagram of the viability of a pellet production plant. have an IRR = 15%, the procurement cost of fiber sorghum from the field cannot exceed the price of A = s91.12/1000 m2. Based on the data for the production of fiber sorghum (Table 3) and the cultivations to be replaced (Table 11) the needed subsidy (Een) is presented Table 29. In Table 29 it can be seen that the needed subsidy is lower than the present for the replacement of all six conventional cultivations. For the replacement of two cultivations (soft wheat and tobacco) almost no subsidy of fiber sorghum for pellet production is needed. It is possible to calculate the differential subsidy DE, if a cultivation area of 29,562 1000 m2 (see Table 26) is replaced. The results are presented in Table 30. From the data in Table 30 it can be seen that in the case of replacement of the conventional cultivations with fiber sorghum for pellet production, a negative subsidy for all the cases is resulted. That means that lower subsidies are needed for the same cultivation areas. Finally, Fig. 11 shows the sensitivity analysis of the differential subsidy as a function of three parameters (efficiency Calculation of the needed subsidy, after replacing six conventional cultivations (for pellets production) To be replaced RCconv RCen (s/1000 m2) Econv (s/1000 m2) H I (s/1000 m2) Een (s/1000 m2) Soft wheat Hard wheat Tobacco Cotton Corn Beet 40.80 40.80 949.20 74.20 39.20 64.20 15.56 48.86 890.00 146.00 51.28 47.00 40.30 38.75 192.50 112.00 118.85 168.69 2.52 29.54 3.68 70.28 16.05 26.63 Table 30 Calculation of the differential subsidy (DE) and the totally needed differential subsidy (DEtot) for power production when replacing six conventional cultivations (for pellet production) Cultivations to Differential subsidy, Total subsidy (s/year) Totally needed differential be replaced DE (s/1000 m2) subsidy, DEtot (s/year) Conventional cultivations Sweet sorghum Soft wheat 18.08 459,991 74,437 534,428 Hard wheat 19.32 1,444,419 873,333 571,086 Tobacco 886.32 26,310,537 108,849 26,201,687 Cotton 75.72 4,316,111 2,077,705 2,238,405 Corn 35.23 1,515,960 474,335 1,041,625 Beet 20.37 1,389,433 787,307 602,126

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 Fig.11.Sensitivityanalysisofthedifferentialsubsidy(DE).of the supply chain, improving of the efficiency of the process, selling price of the pellets). From the diagram it can be seen that 10% rise of the selling price of pellets (from s130 to 143 tonne 1) leads to a decrease at the needed differential subsidy from s 35.23 to 54.56/1000 m2. Furthermore, if there is a process efficiency increase of 10% (e.g. with more efficient drying process in the unit) the needed differential subsidy decreases from s 35.23 to 49.01/ 1000 m2. If, finally, there is a 10% increase in the efficiency of the supply chain (from 70 to 77%), the needed differential subsidy decreases from s 35.23 to 36.79/1000 m2. The improvement of all parameters reduces the differential subsidy to (19.33 + 13.78 + 1.56=)s34.67/1000 m2.

7. Conclusions 总结

In this paper the main costs for biomass use have been discussed. Furthermore, four investment plans have been presented and analysed. The main conclusions from these investment plans are the following: In most of the cases, the subsidy for the cultivation of energy crops should be much higher than the present one of s4.50/ 1000 m2. Fiber sorghum for power production is non-profitable since it needs high subsidy. Therefore an increase of the selling price of electricity from biomass is needed. On the other hand, fiber sorghum used for the production of solid biomass fuel (pellets) is the most profitable from the four energy crops examined. Sweet sorghum (almost in all cases of replacement of conventional cultivations) needs lower subsidies than the conventional cultivations, without the decrease of the profit of the farmers. Sunflower (for its exploitation with a combined unit producing oil and biodiesel) needs, in all replacement cases lower total subsidy without decrease of the profit of the farmers. Fiber sorghum for the production of pellets does not need any subsidy at all when replacing the cultivation of soft wheat and needs very low subsidy for the replacement of tobacco. In the other cases only low subsidy is needed without decrease of the profit of the farmers.

Acknowledg致谢

ments This study was performed for the Institute for Agricultural and Cooperative Economy (INASO) under the coordination of Prof. E. Xanthakis. The study was supported by Piraeus Bank and the Greek Ministry of Development, which, the authors would like to thank. Furthermore, the authors acknowledge work undertaken by the Panhellenic Confederation of Unions of Agricultural Cooperatives (PASEGES), especially Mrs. D. Marda and Mr. M. Smiris.

References 文献

[1] Panoutsou K, Lychnaras B, Namatov E, Nikolaou A. Biofuels in Greece: production potential and environmental consequences. In: Conference RENES; 2004. [2] Greek Ministry of Development. 1st annual report, Athens; 2005. [3] Kyritsis S. Agricultural University of Athens, Department of Agricultural Engineering, Farm Structures Laboratory, Athens; 2006, personal communication. [4] Union zur Fo¨rderung von Oel-und Proteinpflangen E.V. (UFOP). Status report biodiesel—biodiesel production and marketing in Germany, Germany; 2005. [5] United States Department of Agriculture (USDA). Trends in US Agriculture, National Agricultural Statistics Service, USA; 2003. [6] Sims REH, Venturi P. All-year-round harvesting of short rotation coppice eucalyptus compared with the delivered costs of biomass from more conventional short season, harvesting systems. Biomass and Bioenergy 2004;26:27–37. [7] Domalski ES, Jobe TL, Milne TA. Thermodynamic data for biomass and waste incineration, SERI/SP-271-2839. Solar Energy Research Institute and National Bureau of Standards; September 1986. [8] Vaughan L, Shula RG. Options for harvesting and processing firewood. The firewood venture: planning, execution, evaluation, forest research institute bulletin no. 137 (revised edition), Rotorua, New Zealand; 1993 [FRI 68-79]. [9] Ledin S, Sennersby-Forsse L, Wright L. IEA end of task report short rotation forestry production systems 1995–1997; 1998. [10] Network Ltd., Feasibility study for the installation of a 23 MW biomass fired CHP production unit in Crete, Athens; 1998. [11] Steiner E. Ethanol pathways in the 2050 North American transportation futures study. National Renewable Energy Laboratory/NREL; 2003. [12] Boukis I. Study of the feasibility for the realization of conversion units for the production of second generation fuels. Athens; 2006. [13] EC-JRCb, Techno-economic analysis of biodiesel production in the EU— a short summary for decision makers. Institute for Decision Makers, Seville; 2002. [14] Independent Business Feasibility Group (IBFG), LLC. The biodiesel plant development handbook. Kearney, MO; 2002. [15] Greek Ministry of Development. Community support framework 2000– 2006 operational programme ‘‘competitiveness’’, Athens; 2004. [16] Thyson SK, Bozell J, Wallace R, Petersen E, Moens L. Biomass oil analysis: research needs and recommendations, NREL/TP-510-34796; 2004. [17] Eibensteiner F, Danner H. International Energy Agency (IEA). Biodiesel in Europe: systems analysis, non-technical barriers, Task 27. Sysan, IFA; 2000. [18] Berg C. World fuel ethanol—analysis and outlook, F.O. Licht; April 2004. [19] Grassi G. Modern concept for integrated biofuels production. Case Study ECHI-T, EU-China Workshop on Liquid Biofuels, Beijing; 4–5 November 2004. #p#分页标题#e#

I. Boukis et al. / Renewable and Sustainable Energy Reviews 13 (2009) 703–720 [20] International Energy Agency (IEA). Biofuels for transport—an international perspective; 2004. [21] GEAWiegand.Publicationoftherealizationofabioethanolunitincentral Europe from the company, www.geagroup.com; 2005. [22] EC-JRCa. Techno-economic analysis of bio-alcohol production in the EU—a short summary for decision makers. Seville: Institute for Decision Makers; 2002. [23] Ghafoori E, Flynn P. Optimum sizing for anaerobic digestion. BIOCAP Research Project, University of Alberta; 2006. [24] Smirlis M. Data of conventional cultivation, PASEGES, Greek confederation of agricultural partnership; 2006, personal communication. [25] Vassilakos N, Boukis I. Techno-economic & development study for a biomass energy utilisation plant, fuelled by agricultural by-products and residues of the Heraklion Prefecture, prepared for the Regional Agency of Crete in the framework of the ALTENER CONTRACT No. 4130/Z/01-79/2001 ‘‘Joint Opportunities for European Biomass’’; 2003. [26] Tiffany DG, Eidman VR. Factors associated with success of fuel ethanol producers. Staff paper P03-7. Department of Applied Economics, College of Agricultural, Food and Environmental Sciences, University of Minnesota; 2003. [27] CIBE (European Beet Growers’ Association). CIBE Study on Bioethanol Developments in the European Union, CIBE D.174; September 2006. [28] Elobeid A, Tokgoz S. International Ethanol, Food and Agricultural Research Institute (FAPRI), Center for Agricultural and Rural Development, Iowa State University; 2005. [29] Oleoline.com. Glycerine Market Report OGMR; 2004. [30] Zafiris Ch. Center for Renewable Energy Sources (CRES), Athens; 2006, personal communication. [31] Judd B. Feasibility of producing diesel fuels from biomass in New Zealand. Christchurch: Energy Efficiency and Conservation Authority; 2003. [32] Barakos N. The contribution of the production of biofuels from Greek Primary Sources in Agricultural Development. In: Conference of Greek Agriculture; 2006. [33] Amandus Kahl Gruppe, http://www.akahl.de. [34] Thek G, Obernberger I. Wood pellet production costs under Austrian and in comparison with Swedish framework conditions. Biomass Bioenergy 2004;27:671–93.

|

|

|||

| 网站地图 |